Automatic Filling Sealing Coding Trimming Soft Plastic Tubes Machine

1. Main parts of materials are in line with GMP requirements.

2.The machine can inject all kinds of paste, viscosity fluid and other materials into the tubes

3.Capacity of this machine can reach 2400 pieces per hour

4.Filling error is not more than 1%

5.Design concept required by GMP for pharmaceutical equipment

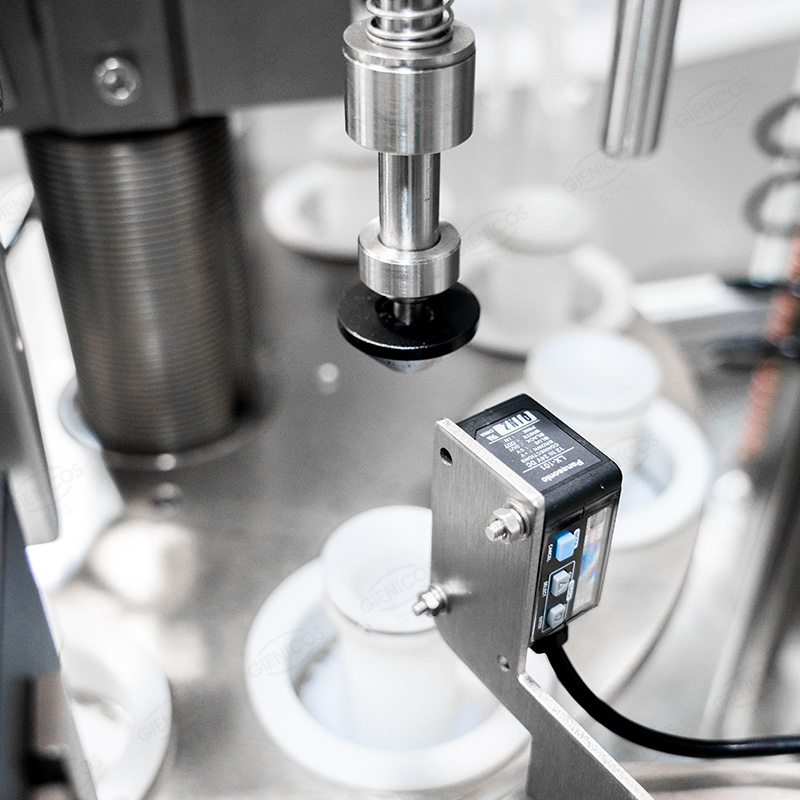

6.Tutomatic feeding of the tube, automatic positioning of the

7.Tube direction, filling, sealing, batch number, finished product discharge

This machine has a high degree of automation and is widely used in the filling and sealing of cosmetics, beauty products, daily chemical products, and medical products.

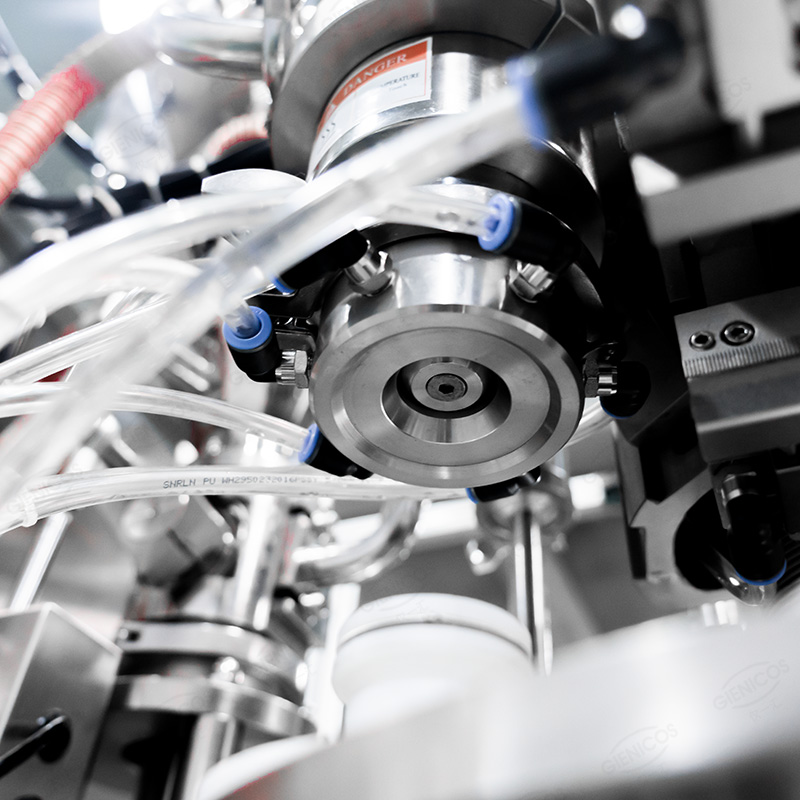

Various high-precision guidance, positioning, feeding, adjustment, detection, vision systems or components are used on the machine equipment to ensure the high precision of product assembly and production.

Significantly increase labor productivity. The product quality is highly repeatable and consistent, which can greatly reduce the failure rate.

Significantly reduce manufacturing costs. The takt time of automatic machine assembly production is very short, which can achieve high productivity, and at the same time, the machine can run continuously, thus greatly reducing manufacturing costs under the condition of mass production.

粉底液转盘式充填机(新增未入册)2-300x300.png)

GIENI双色气垫拉花充填机-全自动控制-300x300.png)