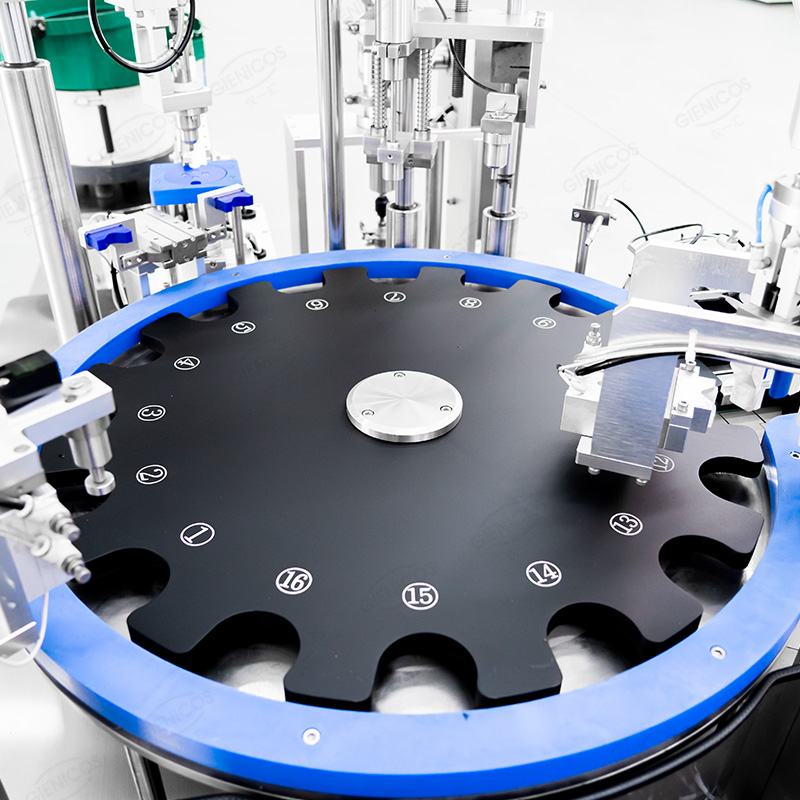

60pcs/min Ointment Cosmetic Packaging Luxury Soft Tube Filling And Sealing Machine

| Dia. of tubes | 19mm; 35mm; 50mm |

| Filling volume | 5ml; 50ml; 200ml |

| Production speed | 60ppm |

| Air source | compressed air 6bar |

| Air consumption | 5cmph (metal tube); 56cmph (heating type) |

| Water consumption | 200L/H (heating type) |

| Power consumption | 1.25kw (metal tube); 5.3kw (heating type); |

| Machine size | 1890*1083*2172mm |

1、The production speed is fast, GFS-60 can reach 60ppm, GFS-80 can reach 80ppm (depending on the material viscosity).

2、It can realize automatic filling, fast production transfer and automatic tail sealing.

3、High precision servo color mark positioning ensures the accuracy of sealing position.

4、Mechanical cam with piston pump filling, to ensure high precision filling volume, especially suitable for filling high viscosity materials.

5、The sealing temperature is controlled by PID, the temperature is stable and the welding quality is high.

6、Mechanical cam makes this equipment stable, long service life, and low defect rate.

7、Equipped with various protection systems, such as overload protection system, door opening and shutdown system, to ensure the safety and stability of use.

8、Sanitary grade 316L stainless steel is selected for parts contacting with materials.

9、Beautiful appearance, compact structure and small occupied area.

10、The key parts are international first class brands, such as Siemens PLC, Schneider

electric components, Yaskawa frequency converter, etc.

11、The operation interface is simple and the fault alarm system is clear.

12、Three levels of operation permission can be set.

13、Double safety line can be used for tail sealing (optional).

14、 R angle sealing can be selected (optional).

15、 Special shaped sealing can be used (optional).

16、Can choose the defective products automatic elimination system, such as color mark positioning

is not accurate, leakage filling, welding temperature is not up to standard and so on (optional).

17、 Large capacity tube hopper can be selected (optional).