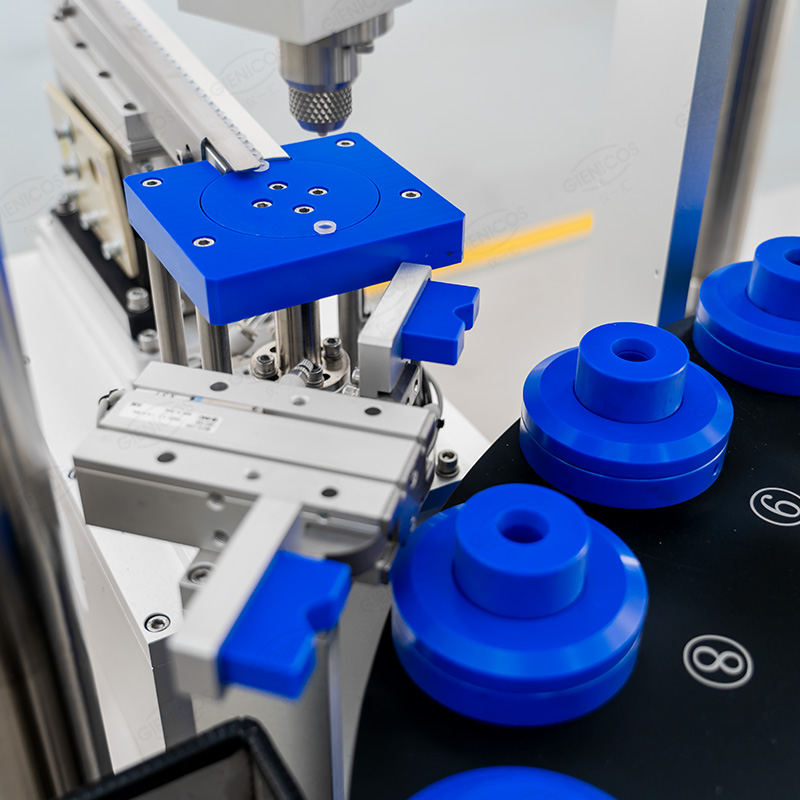

Semi Automatic Single Nozzle Mascara Lipgloss Filling Lip Oil Machine

TECHNICAL PARAMETER

TECHNICAL PARAMETER

Semi Automatic Single Nozzle Mascara Lipgloss Filling Lip Oil Machine

| Dimension | 1750*1100*2200mm |

| Voltage | AC220V,1P,50/60HZ |

| Power | 3.8kw |

| Air Supply | 0.6-0.8Mpa,≥800L/min |

| Capacity | 32-40pcs/min |

| Filling Volume | 2-14ml,10-50ml(By changing spares) |

| Tank Volume | 20L |

Features

Features

- Fast Cleaning Within 3 min—complete the disassembling & cleaning, save the labor cost during production

- 0-50ML Filling Volume Changeable Within 5min---change different spares to achieve different filling volume: 0-14ML, 10-50ML;

- Since the valve is fast joint design, mascara and lipgloss could be used on one machine by fast changing spare.

- Special movement control design ensures the electrical cam running;

- Servo Filling system with nozzle lift up-down, achieve the bottom filling function to avoid bubbles during filling.

- Program setting for auto cap lift up/down before capping, can set times (1-5etc)

- Wide application:can be used for lipgloss, liquid lipstick, lip pud, lip oil and mascara by adding optional function.

Application

Application

- Rotary Filling&Capping Machine For Lipgloss、Mascara、Foundation、Lipoil and other color liquid cosmetic and makeup products.

Why choose us?

Why choose us?

To improve valve connection efficiency, Gienicos uses quick assemble design. After using this device, it is only necessary to move the handle when pressing continuously to realize the quick connection of the valve connecting thread, replacing manual operation, effectively reducing the workload, improving the machine plot and the efficiency of adjustment.

The servo filling system has high precision and easier operation, which can make the enterprise enter the production state faster, thus bringing greater benefits to the enterprise.