Automatic 6 Nozzle Lip Balm Making Hot Filling Line

| Outer dimension | 12000X1700X1890mm (LxWxH) |

| Voltage of Hot Filler | AC220V,1P,50/60HZ |

| Voltage of cooling tunnel | AC380V(220V),3P,50/60HZ |

| Power | 17KW |

| Air supply | 0.6-0.8Mpa,≥800L/min |

| Filling Volume | 2-20ML |

| Output | Max 60pcs/min.(acc.to raw materials&mold quantity) |

| Weight | 1200kg |

| Operator | 1-2 persons |

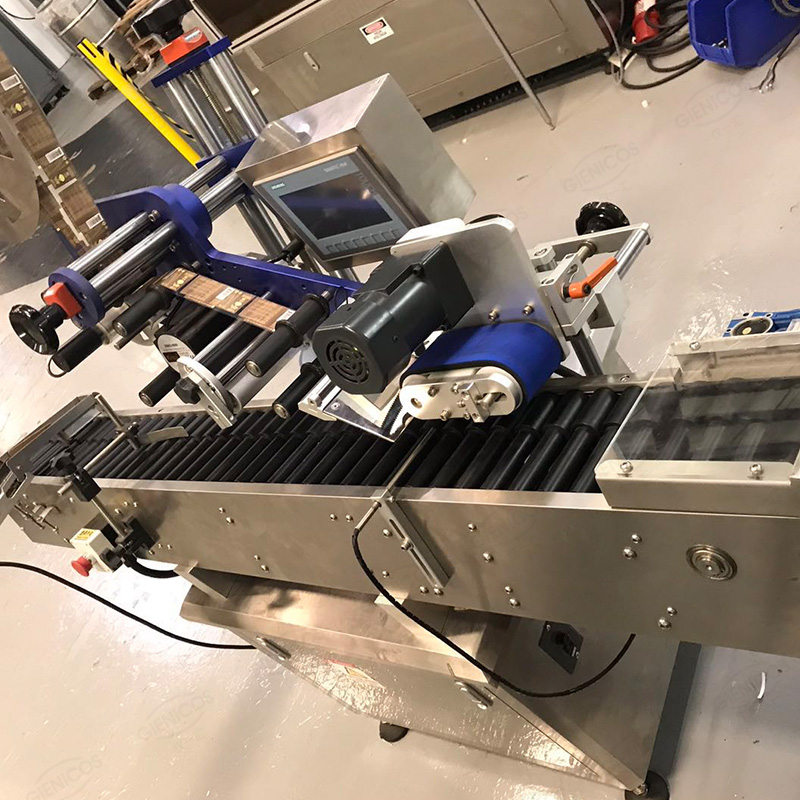

- Auto load tubes, filling precise ,natural cooling reheating circulation cooling reheating, capping, labeling .

- Adopt slate conveyor belt. Cleaning and changing is convenient.

- Fill 6pcs each time and filling precision can reach ±0.1g.

- Pump construction is easy for cleaning, convenient for change material.

- Adopts 7.5P compressor on chilling tunnel with R404A media.

- Pucks circulation method gives the line flexible for different tubes by changing it.

We adopt slate conveyor. The conveying surface is flat and smooth, the friction is small, and the transition of lipstick between conveying lines is smooth. The conveying speed is accurate and stable, which can ensure precise synchronous conveying.

The conveyors can generally be directly washed with water or directly immersed in water, and the equipment is easy to clean.

The structure of the pump body is also easy to clean, and the refueling operation is convenient.

Machine safety performance and precision are relatively high.

Consider the stability and precision of machine operation to the greatest extent.

润唇膏-300x300.png)