20L Lipstick Lip Balm Heating Melting Dissolving Mixing Equipment

-

-

-

-

-

-

- 1.Three layer tank,with heating and mixing(dual stirrer,speed adjustable)

- 2.The tank material is SUS304 and contact part is SUS316l

- 3.6 tanks has individual control, start either of them is able to achieve.

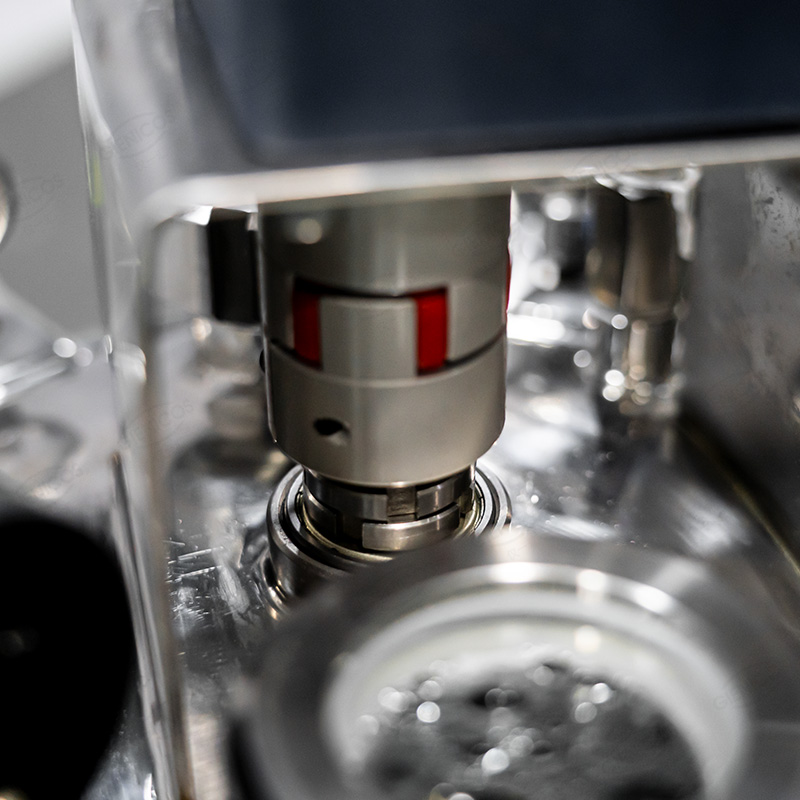

- 4.Easy assemble and disassemble discharging valve.

- 5.Vacuum function adopts vacuum pump,with sight view.

-

-

-

-

-

The machine runs reliably and smoothly, with low noise, few failures and long life.

The appearance is beautiful, the main parts of the shell are closely cast, the structure is firm, the strength is high, and it is not easy to deform.

The multi-barrel design allows manufacturers of lipsticks and other colors that need to be melted to switch colors at will, saving the cost of material cleaning and improving production efficiency. Effectively prevent the bad situation that the various colors of color cosmetics affect each other.

Our machines are highly customizable and can be designed according to the variety of colors and capacity needs. The capacity and quantity of the tank can be customized according to the needs of customers.

The six-in-one design saves production space, and each tank can control the temperature and speed individually, allowing the system to cooperate with the material pre-melting function of multiple filling systems.

It saves the manpower, material resources and space costs of factories that need to process various materials separately.

润唇膏-300x300.png)