Product Detail

Product Tags

TECHNICAL PARAMETER

TECHNICAL PARAMETER

Brief Introduction

Brief Introduction

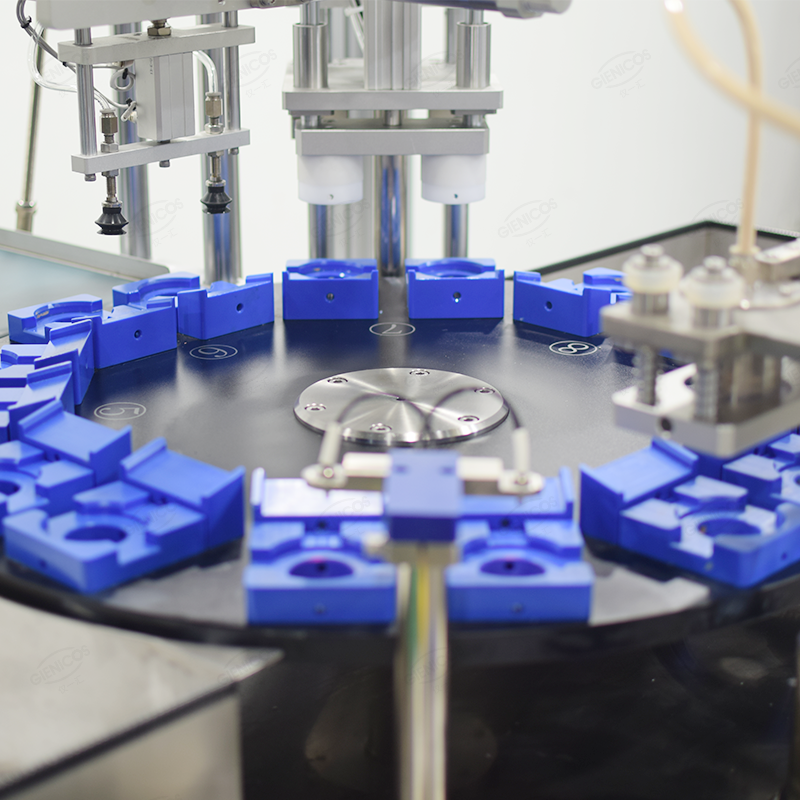

- This line is specially designed for filling lipgloss into bottles, it includes filling/wiper loading/auto capping and auto demolding all in one line. The line speed could reach 40-60pcs/min which is good for mass production.

Working process

Working process

-

-

-

-

-

- Manual load bottle—Auto Filling—Auto load wipers—Auto press wipers-- Manual load the cap—Auto capping—Auto demolding and pickup for convey out

Working process

Working process

-

-

-

-

-

- 1.Max filling volume: 18ml

2.Precision:±0.1g

3.Output:40-60pcs/min (acc. to manual feed speed)

4.Tank volume:20L

5.Bottle body application range: 12-20MM diameter, 50-110MM height

6.Cylinder volume: 1-19ml

7.Bottle body application range: 12-20MM diameter, 50-110MM height Voltage: 220V 1P 50/60HZ

8.Running filling speed: 48-72PCS( 12 nozzles)or 40-60PCS(10 nozzles)

Filling accuracy:within +-0.15g

9.Modular design, later can be purchased according to the order of automatic

plug and automatic screw cap to produce lip glaze, lip gloss (fixtures separately)

Working process

Working process

-

-

-

-

-

- PLC: MITSUBISH

Servo Motor: MITSUBISHI

Touch Screen: Weinwiew

Main Rotary Motor: JSCC

Tank Materials: Parts contacted with product in SUS316L

Working process

Working process

Why choose this machine?

Why choose this machine?

- Increased Efficiency: GIENICOS CC cream filling machine can fill containers much faster and with greater accuracy than manual filling methods, which can increase overall production efficiency.Consistent Filling:GIENICOS CC cream filling machine, you can achieve consistent filling levels across all containers, ensuring that each product meets the same high-quality standards.

Reduced Waste: With accurate and precise filling, GIENICOS CC cream filling machine can help to reduce product waste, which can save money and improve sustainability.

Improved Safety: Using a filling machine can reduce the risk of product contamination and improve worker safety by minimizing the need for manual handling of the product.

Versatility: GIENICOS CC cream filling machine can be used to fill a wide range of container sizes and shapes, making it a versatile solution for different product lines.

Cost-effective: Over time, the use of a filling machine can result in cost savings due to increased production efficiency and reduced waste.

Previous:

High Precision Air Cushion CC Cream Rotary Filling Machine with Auto Pickup

Next:

JR-01P Lip Pouch Rotary Filling Machine