factory low price Essential Oil Filling And Capping Machine - Turnkey Project Essential Oil 4Nozzle Filling Capping Labeling Production Line – GIENI

factory low price Essential Oil Filling And Capping Machine - Turnkey Project Essential Oil 4Nozzle Filling Capping Labeling Production Line – GIENI Detail:

| Voltage | 1P/3P 380V/220V |

| Filling Nozzles | 4 |

| Power | 2.5KW |

| Current | 12A |

| Output | 1800-2400 bottle/hour |

| Air pressure | 0.5-0.8 MPa |

4Nozzle Filling production line is applied for essential oil, face serum, dripper bottle oil etc. It could reach speed at 40pcs/min.

1. The whole line is fully automatic, 1-2 operator is enough to monitor the line and add empty bottles.

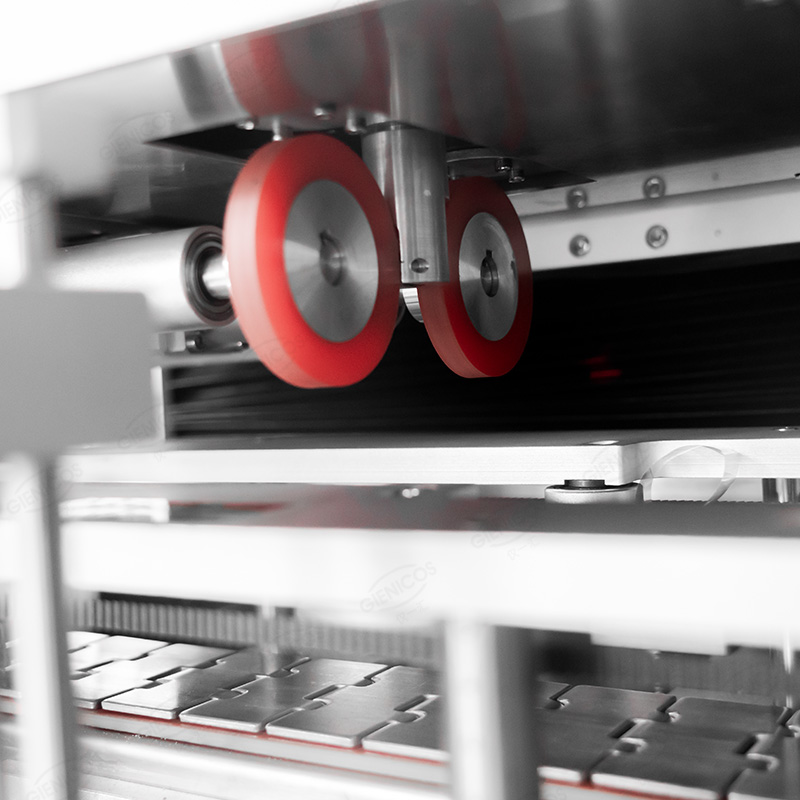

2. 4nozzle filling and capping machine adopts rotary design, full SUS frame and safety door meets GMP standard.

3. Piston filling driven by servo motor results in high filling precision.

4. Filling nozzles are able to be lifted up and down which is also driven by servo motor.

5. Flat caps or dripper caps are both able to be sorted and loaded automatically.

6. Capping system driven by servo motor is self-designed by GIENICOS, the rotary speed/torque are all adjustable.

7. Induction sealing machine adopts water cooling circulation system, high efficiency.

8. High speed sleeve shrink labeling machine is able to do the neck shrink for flat cap.

9. Round bottle labelling machine is well made to do half-round label or full-round label stick on.

10. Buffer rotary table designed after filling and capping machine is to make sure non-stop production when operator replace labels during production.

1. The whole line is fully automatic, 1-2 operator is enough to monitor the line and add empty bottles.

2. 4nozzle filling and capping machine adopts rotary design, full SUS frame and safety door meets GMP standard.

3. Piston filling driven by servo motor results in high filling precision.

4. Filling nozzles are able to be lifted up and down which is also driven by servo motor.

5. Flat caps or dripper caps are both able to be sorted and loaded automatically.

6. Capping system driven by servo motor is self-designed by GIENICOS, the rotary speed/torque are all adjustable.

7. Induction sealing machine adopts water cooling circulation system, high efficiency.

8. High speed sleeve shrink labeling machine is able to do the neck shrink for flat cap.

9. Round bottle labelling machine is well made to do half-round label or full-round label stick on.

10. Buffer rotary table designed after filling and capping machine is to make sure non-stop production when operator replace labels during production.

Product detail pictures:

Related Product Guide:

We take customer-friendly, quality-oriented, integrative, innovative as objectives. Truth and honesty is our management ideal for factory low price Essential Oil Filling And Capping Machine - Turnkey Project Essential Oil 4Nozzle Filling Capping Labeling Production Line – GIENI , The product will supply to all over the world, such as: Surabaya, Malta, Haiti, With many years good service and development, we have a qualified international trade sales team. Our goods have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!